Curie Point

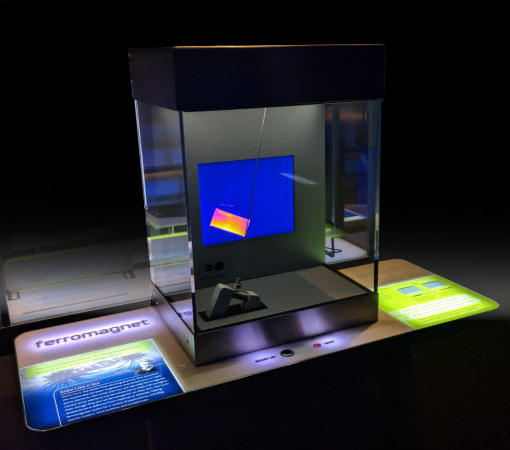

Interactive Exhibit for the Museum of Science and Industry, Chicago

When The Museum of Science and Industry proposed the idea of a development for a new interactive exhibit in the museum’s science storms gallery, we were over the moon! Our friends aspired to educate visitors on how increasing metal gradually affects their magnetic properties. Sounds like something that would attract a lot of people (no pun intended). Picture heating a piece of metal to almost 700°F in a few seconds, allow it to cool and make that repeatable hundreds of times a day 360 days a year for 30 years.

Curie point is the given name for the ideal temperature point when specific materials begin to lose their magnetic properties. A permanent magnet has two dipoles, that are aligned at a normal state. In this state, the atoms of the ferromagnetic metal inside a magnet are aligned and act like tiny magnets when they have not hit their Curie point. When the metal is heated, the atoms begin to vibrate and lose the dipole alignment. When the metal temperature is brought down, the atoms will then realign and the metal will regain its magnetism.

Well, we actually worked with anatomically-correct 3D models of these critters. As a result, we were able to “dissect” the frog shapes virtually, 3D carve them on our CNC router, then reassemble the parts back into their final shapes. Luckily, custom-engineered tooling allowed us to CNC carve in 12″ thick sections!

Safety being our biggest priority, this interactive exhibit features multiple fail-safes for voltage, temperature and pendulum position. For this display, we dealt with high voltage and extreme heat, so it was imperative to create an on/off switch to ensure safety and security. When opened up, our melting machine consisted of the following: Machined aluminum housings with ceramic bushings to hold the custom manufactured nickel tubing and conceal an industrial grade induction heater. We also utilized a highly customized infrared camera with a software package that senses temperature and pendulum position.

Let's talk about the process. This project had many challenges. First of all, the whole scenic design was to be viewed from a full 360 degrees. Secondly, the elements needed to be lightweight but strong. Installing anything from hanging points 135-feet in the air is not easy. How does one begin to make gargantuan amphibians?

At room temperature, the permanent magnet and nickel are attracted to each other. However, heating the nickel tube allows our pendulum to swing away from the magnet. Once the tube is brought back down below 354 degrees Celsius, the nickel is then magnetically attracted to the magnet again.We also set up a special particle-free environment to prevent dust and foreign particulates from infiltrating the resin as it cured. We even hit the surface with a blowtorch, much like brazing a Crème Brûlée, to prevent air bubbles from getting trapped inside of the material.

Finally, we were up to the challenge of installing the frogs from hanging points 135-feet in the air. After two nights of careful installation, we were able to create full exposure for these frogs without using specimen pins.

In 2015, the Museum of Science and Industry saw 1.5 million visitors, and we built an interactive museum display to last! We love a good challenge and this project was just what we needed to force (again, no pun intended) us to create the biggest and best display possible.